At the moment there is no defined energy class for water dispensers, but this does not mean that energy consumption cannot be reduced.

The efficiency of the refrigeration circuit is certainly one of the main aspects, having a high COP means making good use of energy absorbed by the refrigeration circuit to cool the drinking water.

Another important factor is thermal insulation, easy to do in hermetic systems for example in our MF20 where all the saturator and the thermal flywheel are well insulated. They are dispensers intended for domestic use or for the office where a significant thermal flywheel is not required

Thermal insulation in aluminum blocks is not easy and the dispersion is not negligible.

The ice bank is to be considered with care. The water contained in the tank has a free surface in contact with the air that circulates inside the system. In addition to the condensation, the heat exchange is remarkable with a high consumption of thermal energy which is dispersed.

How to save energy in ice bank cold and sparkling water dispensers?

Completely switching off an ice bank system is not productive for two reasons, the first is that from switching on the appliance it can take up to two hours, the second is that restarting has a higher energy cost due to a decrease in COP.

The solution ? Minimize the heat exchange and put all the parts that are not needed on standby.

Why put the agitator on stand-by in dead times

Let’s see what dead times are.

The ice bank agitator is essential when the refrigeration circuit works and when water is dispensed. It serves to remove the layer of cold water along the walls of the ice bank and therefore exploit its power, as well as to remove the film of hot water on the walls of the coil, to improve heat exchange. It serves for a homogeneous development of the walls of the ice bank, it serves to make the thermostat work correctly.

As we said a little above, the agitator is used when I make ice and when I tap cold or sparkling water, but in other periods it is dead time and the agitator is of little use except for consuming and wasting energy.

Consuming and wasting Energy because the power of the agitator motor, even if modest, is not zero, (for example the SAP T2 model absorbs 35 Watts)

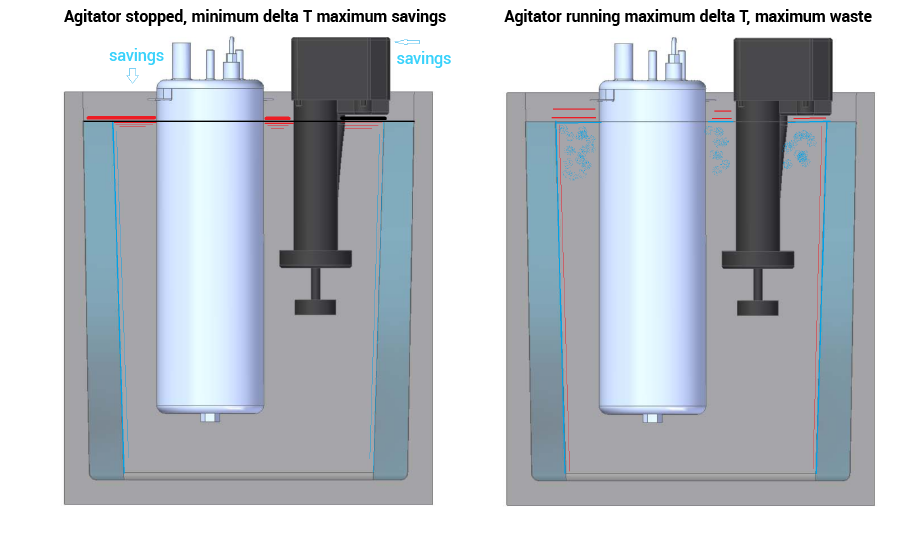

Dispersion of energy for the free surface of the ice bank from a static lamirar convection becomes turbulent with greater dispersion of energy. In the following diagram it can be seen that the flapping of the water by removing the layer of hot water on the upper free surface and of cold water on the walls increases the heat exchange, certainly not required in downtime

In addition to this, if the python is present, the loss of thermal energy in dead times is very high.

How much energy and money can be saved by making the agitator work only when needed?

Two quick calculationsI assume it only serves 8 hours and not 24Electric absorption of the agitator 35 Watt x 16 hoursThermal energy not dispersed by recirculation approximately 8% of the power of the 265 Watt compressor, i.e. 21 Watt for 16 hoursheat exchange, (lower global heat transfer coefficient, lower delta T) 12 Watt x 16 hours

Approximately 1700 Watts are saved in one day, i.e. 1.7 kWatth, in a hypothesized an opening of 290 days approximately 487 kWh, at an average cost of 0.35 €/kWatth the result is 170 € !!!

As a final note, we must consider that the organ in question, if used less, wears out less and lasts longer.

GWS Industries has developed a device for ice bank machines to operate the stirrer only when needed, MF90+ and MF50+, soon also M120+