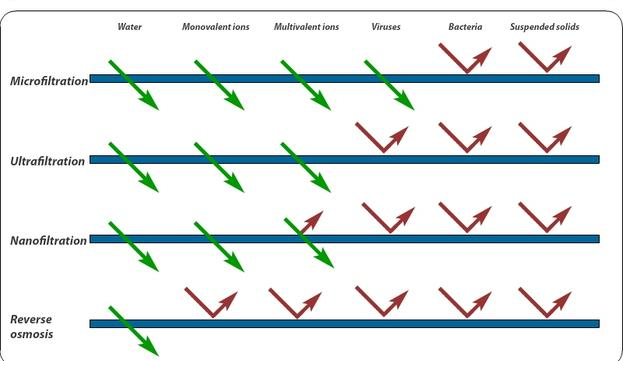

A die-hard urban legend claims that the reverse osmosis plant would be a mechanical barrier capable of stopping particles with size in the order of 20 billionths of a meter, i.e., for all substances, thus including microorganisms, with size greater than the porosity of the membrane.

The membrane of the osmosis system actually has the ability to stop microorganisms, from micrometer-sized bacteria to nano-metric-sized viruses. The prefix micro indicates a reduction of a million times smaller than the meter, while the prefix nano indicates a reduction on the order of a billionth.

Membrane and reverse osmosis plant are two distinct things, however. While it is true that the membrane has the ability to stop even viruses (like ultra filtration and nano filtration for that matter) it is not always true that the plant is not an absolute barrier and there are critical points to keep in mind.

Reverse osmosis system and operation regime

In hydraulic systems, the operating regime can be transient or permanent. The former is a temporary or otherwise unstable use in which flow rate and pressure change over time, while the permanent regime assumes a constant pressure and flow rate over time. The permanent regime is the simplest to analyse in terms of the risk factors, while the thermporary regime raises several questions.

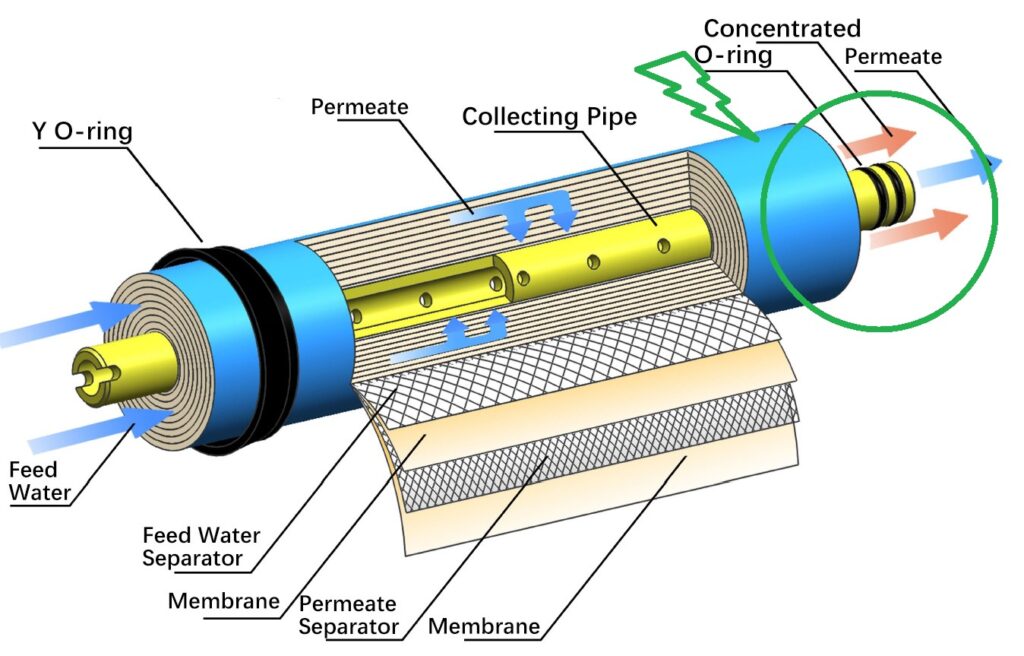

This diagram clearly shows how a reverse osmosis membrane for a domestic device is structured

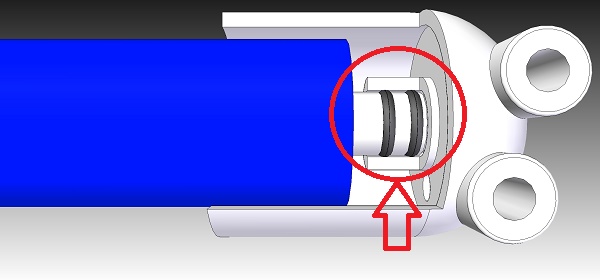

In the part circled in green, the ORs, i.e. the sealing gaskets, which serve to fit the membrane in its vessel, are highlighted.

While it is true that the membrane has a tolerance of 0.00002 mm, in the case of these seals we are in the order of 0.1 mm.

As long as the regime is permanent, with plenty of flow, the fact that there is a mini leak is of little importance, the water produced is completely healthy.

The problem arises when the regime is temporary and there are long downtimes. Through this ‘leak’, any micro-organisms present pass over the membrane.

Vessel – Membrane Coupling

This is one of the critical points, which in combination with low-quality prefilters leads to bacterial proliferation downstream of the membranes. To reduce this risk factor, in addition to good quality vessels, we recommend the use of good quality prefilters with antimicrobial aditives such as silver salts.

The lack of a non-return valve on the reject, poses problems of back-contamination, which if associated with a transient regime can become serious. (We have investigated connectors with UV C LED as a firewall on the reject).